Welding manufacturing stands as a cornerstone of modern industries. Expert John Smith, a leader in welding technology, once stated, "Welding is where innovation meets necessity." His words reflect the vital role of welding in creating robust structures and products.

Welding manufacturing plays an essential role in various sectors, including construction, automotive, and aerospace. The precision and strength it provides are unmatched. Even with advancements, the industry faces challenges, such as skill gaps and safety concerns. These hurdles make it crucial for companies to adapt and train workers continuously.

Moreover, welding manufacturing can sometimes be overlooked in discussions of technological progress. This oversight can hinder advancements and innovation strategies in industries relying on welding. As the demand for sustainable solutions rises, the welding sector must reflect on its practices. Embracing new technologies while maintaining traditional skills is complex but essential for the future.

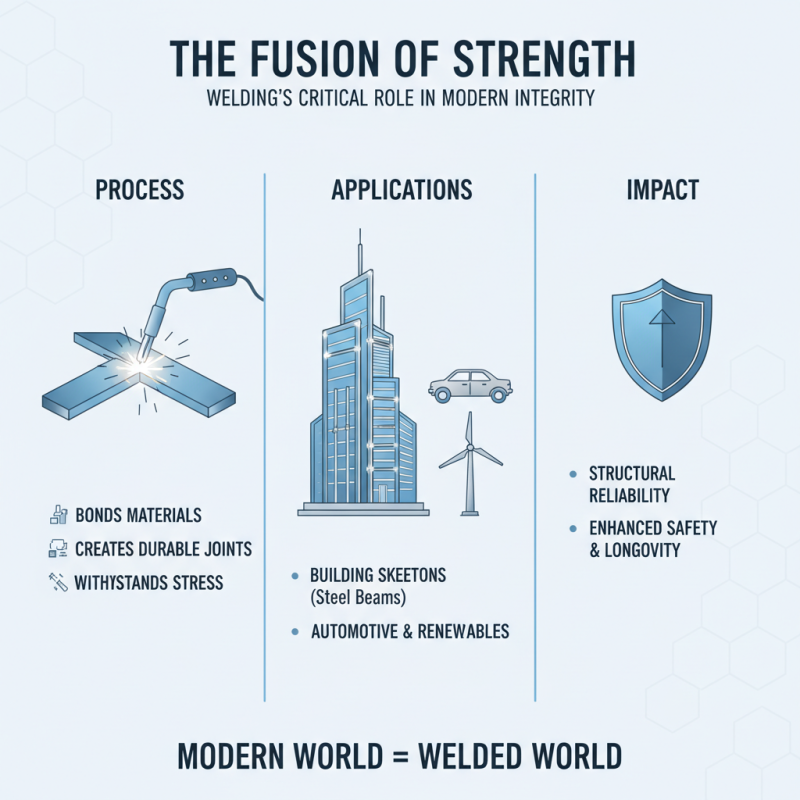

Welding plays a critical role in ensuring the structural integrity of modern products. This process binds materials together, creating strong joints that can withstand various stresses. For example, in the construction of buildings, welded steel beams provide essential support. These beams need to be reliable and durable to maintain safety.

However, welding is not without its challenges. Improper techniques can lead to weak points in a structure. A poorly executed weld may appear solid, but it can fail under pressure. This reality highlights the importance of skilled welders who understand the nuances of the craft.

Moreover, advancements in technology have introduced new welding methods. Though these innovations improve efficiency, they require continuous learning. Welders must adapt to new tools and techniques. Maintaining a balance between tradition and innovation is tough, but it’s vital for quality. Continuous reevaluation of skills and methods is crucial in the industry.

Welding manufacturing plays a pivotal role in various industries. The automotive sector heavily relies on welding techniques to ensure vehicle safety and structural integrity. Statistics show that over 70% of vehicle assembly involves welding. This process enhances production efficiency and reduces costs. Steel frames and body panels are often joined through welding, proving essential for durability.

The construction industry also greatly benefits from welding. Buildings and bridges use welded steel frameworks due to their strength and adaptability. Reports indicate that 50% of all steel used in construction is welded. However, not all welding processes are flawless. Issues like misalignment during welding can lead to structural weaknesses. Continuous training in welding standards is crucial to minimize these errors.

Manufacturing equipment spans diverse sectors like aerospace and shipbuilding. Welding ensures components withstand high pressure and harsh environments. Yet, despite technological advances, weld quality can vary. Regular inspections are necessary to maintain safety. These industries must continuously adapt, as the need for skilled welders grows. With a deeper understanding, we can refine welding techniques to achieve better results.

Welding manufacturing plays a crucial role in modern industries. With continuous advancements, welding technology is evolving rapidly. Automation is now a fundamental aspect that enhances productivity. Robotic welders improve accuracy and efficiency. They can work tirelessly, completing tasks faster than manual laborers.

However, with these improvements come challenges. Workers must adapt to new systems and technologies. Training becomes essential to ensure safety and efficiency. Keep in mind that not all advanced equipment is user-friendly. Inadequate training could lead to costly mistakes.

Tip: Always invest in proper training for your workforce. This minimizes errors and boosts morale.

Welding techniques are also diversifying. From laser welding to friction stir welding, the options are growing. Each method has its unique benefits. Companies need to evaluate their specific needs. Experimenting with new techniques can pose risks but also rewards.

Tip: Document the results of any new welding method you try. Analyzing these results helps in making informed decisions.

Welding manufacturing plays a crucial role in modern industries. Yet, sustainability in welding practices is becoming increasingly vital. According to a report by the American Welding Society, welding accounts for over 60% of all fabricated metal products. As industries grow, so does the need for sustainable practices.

Using energy-efficient technologies is essential. Implementing techniques such as TIG welding can reduce waste and energy consumption significantly. Companies can lower their carbon footprint by adopting new materials, like high-strength steels and aluminum alloys. A study shows that reducing material waste by just 10% can lead to substantial cost savings and environmental benefits.

Tip: Train your team on sustainable welding techniques to increase efficiency.

Welding generates harmful emissions. It's crucial to monitor and manage these emissions to protect workers and the environment. Some industries still overlook this responsibility. Integrating practices that limit pollution is necessary. Using advanced filtration systems can capture up to 90% of harmful particles.

Tip: Regularly review your welding processes for eco-friendliness.

Progress is possible, but many companies struggle with implementing sustainable practices. Addressing this gap can lead to innovation and improved profitability. The welding industry must continually reflect on its methods for a better future.

Welding manufacturing is crucial in an ever-evolving industrial landscape. As industries embrace advanced technology, welding remains at the heart of production processes. For instance, the global welding market was valued at approximately $22 billion in 2021 and is projected to reach around $30 billion by 2027. This growth reflects the rising need for efficient and durable connections across various sectors, including automotive, construction, and aerospace.

The future of welding will see increased automation. Robotic welding systems enhance precision and speed. However, this shift may lead to a skills gap as traditional welders need to adapt. Reports indicate that by 2025, approximately 2 million manufacturing jobs could go unfilled due to a lack of skilled workers. Companies must invest in training programs to prepare the next generation for these advanced technologies.

**Tips:** Consider joining local welding workshops. Hands-on experience boosts understanding. Stay updated with industrial trends through online courses. Networking with professionals can provide valuable insights. Reflect on challenges and opportunities within your work environment. Embracing change is vital for personal and industry growth.

This bar chart illustrates the distribution of welding applications across various modern industries, highlighting their significance in construction, automotive, aerospace, and energy sectors.