In 2026, state contract manufacturing continues to evolve. This sector serves as a crucial backbone for various industries. According to a recent report by the Industry Research Institute, the market for state contract manufacturing is projected to grow by 15% annually. This growth reflects increasing demand for specialized manufacturing services.

Daniel Thorne, a leading expert in state contract manufacturing, states, “Flexibility and innovation will define the future of this industry.” Businesses are realizing they can reduce costs by outsourcing production. However, choosing the right partner remains a challenge. Many companies face hurdles, such as inconsistent quality and communication delays.

Despite technological advancements, not all manufacturers have adapted effectively. Many struggle to meet the fast-paced needs of the market. In 2026, addressing these issues will be essential for success. Businesses must navigate this complex landscape wisely. The top ten state contract manufacturing services should be scrutinized for their ability to innovate and adapt.

State contract manufacturing services play a crucial role in today's supply chain landscape. These services allow states to partner with manufacturers to produce goods efficiently. By leveraging local resources, these partnerships can enhance production speed and reduce costs. Many states have begun to recognize the importance of such collaborations, particularly in industries like health care and electronics.

In 2026, we can expect more states to foster these relationships. Local manufacturers are adapting to meet government needs. This can lead to innovation but also raises questions about quality control. Not all partnerships yield the desired results. Some projects may face delays or budget overruns. It is essential for states to carefully evaluate their manufacturing partners.

Suppliers must align with state goals and standards. Transparency becomes vital. Both parties should clearly communicate expectations. As the demand for contract manufacturing services grows, states must remain vigilant about their selection processes. A one-size-fits-all approach will not work in every case. Each state has unique needs that should be addressed individually.

| Rank | State | Manufacturing Type | Industry Focus | Annual Revenue (Million $) | Employee Count |

|---|---|---|---|---|---|

| 1 | California | Electronics | Technology | 500 | 1500 |

| 2 | Texas | Automotive | Transportation | 600 | 2000 |

| 3 | Michigan | Aerospace | Defense | 450 | 1200 |

| 4 | New York | Pharmaceuticals | Health Care | 550 | 1800 |

| 5 | Ohio | Industrial Equipment | Manufacturing | 400 | 1600 |

| 6 | Illinois | Food Processing | Food & Beverage | 300 | 800 |

| 7 | Florida | Cosmetics | Beauty | 250 | 600 |

| 8 | North Carolina | Textiles | Apparel | 200 | 500 |

| 9 | Virginia | Biotechnology | Health Care | 350 | 900 |

| 10 | Massachusetts | Robotics | Engineering | 400 | 1100 |

When evaluating contract manufacturing services, several criteria come into play. Quality assurance is paramount. Checking certifications can reveal much about a manufacturer’s capabilities. Inspecting their processes ensures they meet industry standards. It’s vital to assess their quality control measures. Reliable suppliers tend to have robust mechanisms in place.

Another important factor is communication. Clear, timely communication leads to better partnerships. Gauge how responsive potential partners are. Poor communication can result in misunderstandings. Additionally, consider the flexibility of the service. Can they adapt to changing demands? A good manufacturer should accommodate fluctuations.

Lastly, the cost needs careful evaluation. Low prices might attract attention, but they can be deceptive. Balancing quality with affordability is key. Evaluating the total cost of ownership is essential. Scrutinize hidden costs that may emerge later in the process. Reflecting on these criteria can help forge better partnerships.

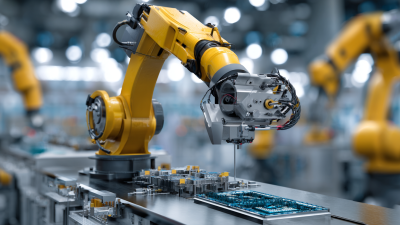

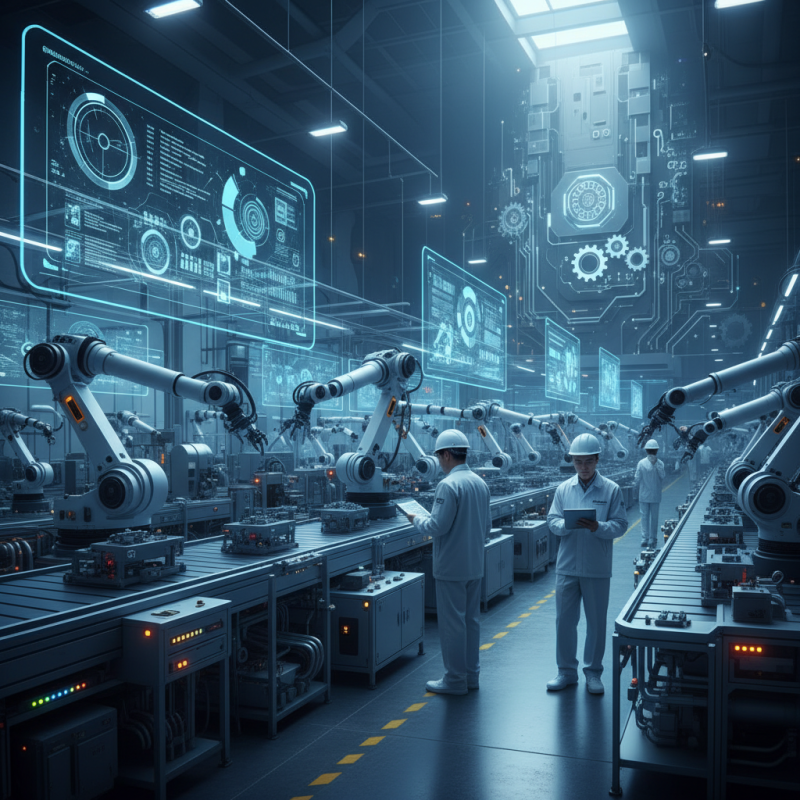

The landscape of state contract manufacturing services is evolving rapidly in 2026. Companies are seeking reliable partners to streamline production processes. This demand has led to an increase in innovative technologies and methods. Many manufacturers are adopting automation and advanced analytics to boost efficiency.

However, not all providers meet industry standards. Some may lack experience or capability. It is crucial for businesses to conduct thorough research when selecting partners. A successful collaboration can significantly reduce time to market and costs. Yet, potential pitfalls exist, such as miscommunication or service inconsistencies.

Investing in state contract manufacturing can yield substantial benefits. Still, companies must remain vigilant. They need to evaluate the quality of services carefully. Engaging with a manufacturer that understands specific needs can facilitate growth. It's a journey worth navigating, but attention to detail makes all the difference.

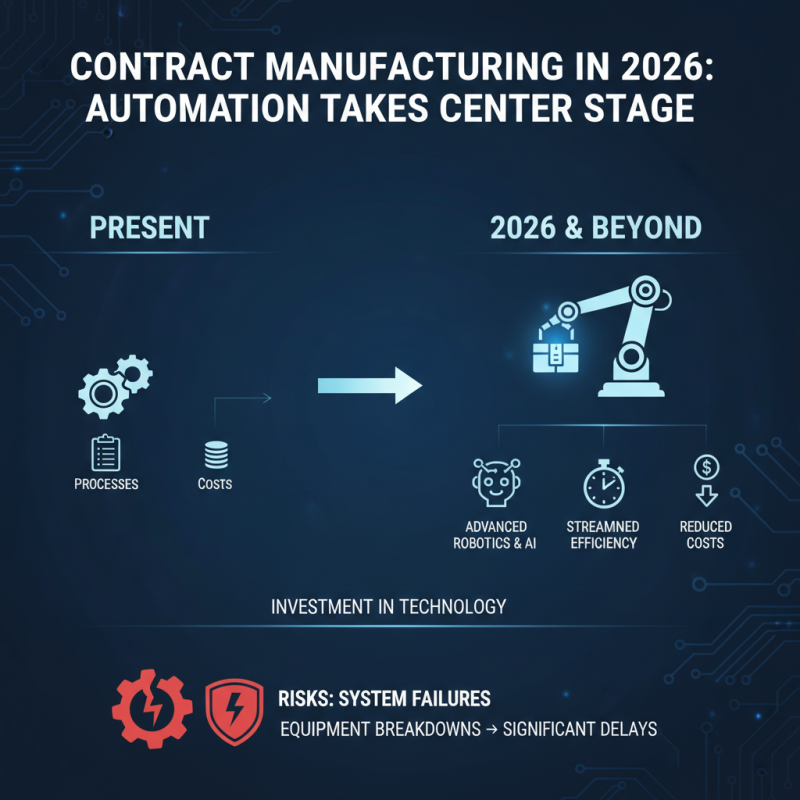

This chart represents the manufacturing efficiency scores of the top 10 states providing contract manufacturing services in 2026. Each score reflects the state's capability to deliver efficient and quality manufacturing solutions.

The landscape of contract manufacturing is rapidly transforming. In 2026, we will see automation taking center stage. Companies are investing in advanced robotics and AI to streamline processes. This transition aims to reduce costs and improve efficiency. However, reliance on technology poses risks. What happens when systems fail? These equipment breakdowns could lead to significant delays.

Sustainability is another critical trend. Many manufacturers are seeking eco-friendly practices. They focus on reducing waste and utilizing renewable resources. It’s a step in the right direction. Yet, implementing these changes can be challenging. Companies often face resistance from their workforce and supply chain. Maintaining quality while going green requires careful planning.

Customization will become even more essential. Clients demand tailored solutions to meet their unique needs. This demand pushes manufacturers to be flexible and responsive. However, flexibility can come at a price. Balancing customization with standardization is tricky. Many firms must reassess their strategies to avoid overextending resources.

Partnering with state contract manufacturers offers various benefits. First, it enhances production efficiency. According to a recent report by the National Association of Manufacturers, over 70% of companies reported improved turnaround times after outsourcing. This allows businesses to focus on strategic initiatives rather than production details.

Cost reduction is another significant advantage. A study by Deloitte found that companies can save up to 25% on manufacturing costs by partnering with local state contract manufacturers. They provide access to skilled labor and advanced technology without the burden of heavy capital investments. Companies often find that they achieve better quality control with these partnerships. However, it's crucial to choose a manufacturer that aligns with your quality standards.

Flexibility also plays a key role. State contract manufacturers can adapt quickly to changes in demand. They often have the capacity to scale operations up or down, a necessity in today’s volatile market. Yet, businesses must remain vigilant. Not every manufacturer can meet shifting requirements or deadlines effectively, making due diligence essential. Engaging with the right partner can yield significant rewards, but risks remain that need careful consideration.