In 2026, mfg manufacturing faces new challenges and opportunities. Studies indicate that companies adopting advanced technologies could achieve up to 30% efficiency gains. Yet, many organizations still lag behind. For instance, a recent survey revealed that only 45% of manufacturers are utilizing smart technologies effectively.

Embracing automation, data analytics, and lean practices is crucial. However, not all companies implement these strategies successfully. In fact, a staggering 70% of mfg manufacturing initiatives fail due to poor execution. This highlights a need for reflection on existing practices and processes.

To thrive, manufacturers must prioritize workforce training and embrace a culture of continuous improvement. Data from McKinsey suggests that firms investing in employee upskilling see productivity rise by 20%. The path to greater efficiency is not without hurdles, but addressing these issues can lead to significant gains in mfg manufacturing.

Understanding manufacturing efficiency in 2026 requires a grasp of key metrics. Efficiency is not just about speed. It's also about quality, utilization, and waste reduction. Important metrics include Overall Equipment Efficiency (OEE) and cycle time. OEE measures how effectively equipment is used. It combines availability, performance, and quality metrics. A lower OEE indicates room for improvement.

Cycle time is crucial for understanding production speed. It tracks the total time to produce one unit. Long cycle times can slow down operations, affecting profits. Regularly assessing these metrics helps identify inefficiencies. Sometimes, companies overlook hidden costs like downtime and maintenance. These can significantly impact efficiency.

Additionally, employee engagement plays a role. Motivated employees often work faster and more accurately. Regular training and feedback can enhance their skills. However, it's easy to assume everyone is performing at their best. Continuous monitoring and adjustment are essential for maximizing efficiency. Companies must remain adaptable to the evolving manufacturing landscape.

This chart represents the predicted efficiency improvements based on best practices in manufacturing for the year 2026. The metrics include Lean Manufacturing, Automation, Employee Training, and Maintenance Management.

Lean manufacturing principles are crucial for enhancing productivity in 2026. These practices focus on minimizing waste while maximizing value. They promote continuous improvement and efficiency.

One effective strategy involves regularly assessing workflows. Look for bottlenecks or inefficiencies. Small changes can lead to big improvements. Engage employees in finding solutions. Often, they have insights that management might overlook.

Implementing standardized work procedures can also help. This creates clarity and consistency. It reduces variability in tasks. Measure key performance indicators to track progress. Adjust your methods based on the data you gather.

Regular training sessions can reinforce lean principles. Employees should feel empowered to suggest improvements. Create a culture that values feedback. It's essential to foster open communication channels. This will help identify issues before they become significant problems.

In the fast-evolving landscape of manufacturing, automation and robotics play a crucial role in enhancing efficiency. By 2026, reports indicate that companies implementing advanced robotics could see productivity increases of up to 30%. This shift helps reduce labor costs and minimizes errors in production. However, the transition is not without challenges. Many businesses struggle with integrating these technologies into their existing workflows.

Tips: Start small. Experiment with pilot programs before larger investments. Analyze how automation interacts with your team and processes.

The adoption of robotics should balance efficiency with workforce management. A survey revealed that 45% of workers believe automation threatens their job security. Addressing these concerns is vital. Effective communication and training can alleviate fears. Companies focused on upskilling their workforce tend to experience smoother transitions.

Tips: Regularly engage with your employees. Gather feedback on their experiences and concerns. This can foster a more inclusive atmosphere.

Automation and robotics are not a magic bullet. Continuous evaluation of their impact is necessary. Adjustments may be needed to ensure alignment with overall business goals and employee satisfaction. The key is to view these technologies as tools to enhance human capabilities rather than replace them.

In 2026, manufacturing efficiency hinges on data analytics. Companies can no longer operate on gut feeling alone. Integrating analytics into daily operations can transform decision-making processes. Data provides insights that drive efficiency and productivity.

Tip: Start small. Implement data analysis tools in a single department first. Monitor the outcomes closely. This allows for adjustments before a company-wide rollout. Many firms rush to apply analytics broadly, only to find disjointed results. Focusing on one area helps refine approaches.

Train employees to interpret data effectively. Not everyone is a data expert. Offer workshops or courses. This can foster a culture of data-driven thinking. Patience is key; results may not be immediate. Individuals might resist new practices, but persistence pays off.

Tip: Regularly review your analytics processes. Data alone isn't enough. Ensure accuracy and relevance. Mistakes can lead to poor decisions. Encourage feedback from teams. This creates a cycle of improvement, focusing on what works and what doesn’t.

Data analytics shapes the future of manufacturing, but success requires continuous adaptation. It’s a journey filled with challenges and opportunities for growth. Embrace the imperfections, learn from them, and evolve.

| Best Practice | Description | Expected Impact | Implementation Timeline | Data Analytics Tools |

|---|---|---|---|---|

| Predictive Maintenance | Using data analytics to predict equipment failures before they occur. | Reduce downtime and maintenance costs by 20%. | 6 months | Machine Learning Algorithms |

| Real-time Inventory Tracking | Implementing IoT devices to monitor inventory levels in real-time. | Eliminate stockouts and overstock situations. | 3 months | RFID and IoT Analytics |

| Supply Chain Optimization | Analyzing supply chain data to streamline operations. | Increase efficiency by 15%. | 1 year | Data Visualization Tools |

| Workforce Analytics | Using data to optimize workforce allocation and productivity. | Enhance workforce productivity by 10%. | 9 months | HR Analytics Software |

| Quality Control Analytics | Using data to monitor and improve product quality. | Reduce defects by 30%. | 6 months | Statistical Process Control Tools |

| Energy Consumption Analysis | Analyzing energy usage patterns to reduce waste. | Lower energy costs by 25%. | 4 months | Energy Management Software |

| Automation Integration | Integrating robotics and AI for production automation. | Increase production speed by 40%. | 1 year | Robotic Process Automation Tools |

| Customer Feedback Analysis | Leveraging customer data to tailor products/services. | Improve customer satisfaction rates by 15%. | 5 months | Sentiment Analysis Tools |

| Data-Driven Decision Making | Utilizing data analytics to inform strategic decisions. | Optimize operations and enhance profitability. | Ongoing | Business Intelligence Tools |

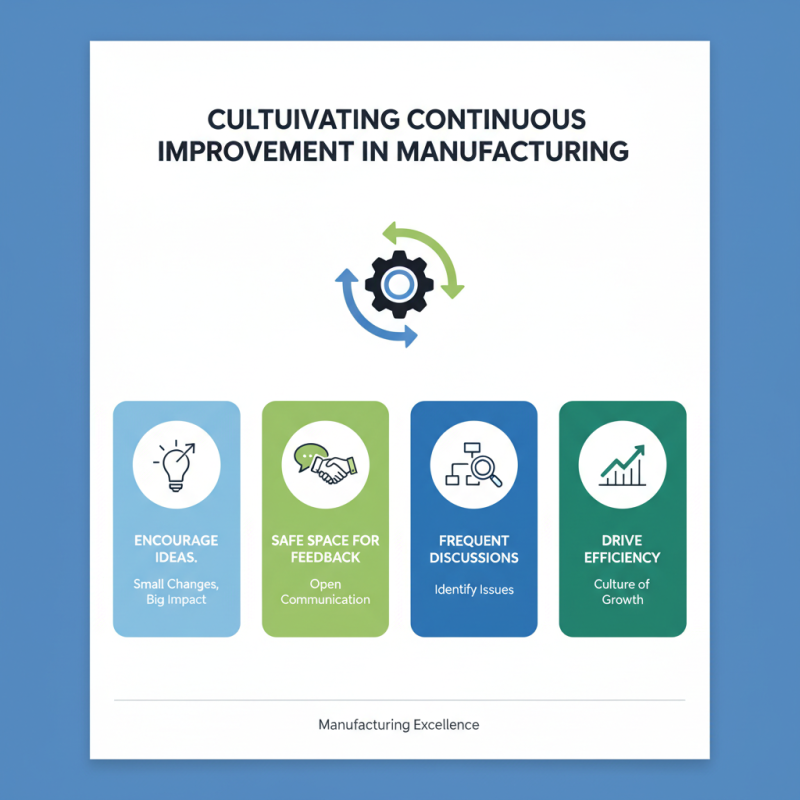

Cultivating a continuous improvement culture in manufacturing teams is essential for efficiency. This culture encourages employees to suggest changes. Small ideas can lead to big improvements. Teams must feel comfortable sharing feedback. Frequent discussions about processes can highlight issues. A safe space for communication is crucial.

Implementing regular training sessions is beneficial. They provide opportunities for skill enhancement. However, not every employee may engage fully. Some may resist change. Addressing these concerns openly can help. Encourage team members to reflect on their work. What worked well? What didn’t? Such reflection can uncover potential improvements.

Recognition of contributions fosters motivation. Celebrate even small wins to maintain enthusiasm. Yet, be cautious not to overlook those who may feel ignored. Everyone should see the impact of their efforts. Continuous improvement is a journey, not a destination. Understanding that not every change will yield perfect results is vital. Embrace the process and learn from failures.