In the rapidly evolving landscape of modern industries, parts manufacturing stands at the forefront, driving change and innovation across various sectors. As highlighted by Dr. Emily Carter, a leading expert in the field, "The future of industry relies heavily on the efficiency and precision of parts manufacturing." This statement encapsulates the transformative power of advanced manufacturing techniques, which are not only enhancing product quality but also reshaping production processes to meet the demands of a dynamic market.

In recent years, the adoption of cutting-edge technologies such as 3D printing, automation, and smart manufacturing has revolutionized how components are produced. These advancements have made parts manufacturing more agile and cost-effective, allowing companies to tailor their products to specific customer needs while minimizing waste. As industries continue to embrace these innovations, understanding the fundamentals of parts manufacturing will be key for businesses aiming to maintain competitive advantages and capitalize on emerging opportunities.

As we delve deeper into the topic of how parts manufacturing is revolutionizing modern industries, we will explore the various methodologies, technologies, and trends that are redefining this essential field. From enhancing supply chains to fostering sustainability, the potential for growth and improvement in parts manufacturing is vast and promises to unlock a future filled with possibilities.

Parts manufacturing is undergoing a remarkable transformation due to groundbreaking technologies that are reshaping modern industries. Advanced manufacturing methods such as 3D printing, automation, and artificial intelligence are not only increasing efficiency but also enabling customization at an unprecedented scale. These innovations allow manufacturers to produce complex parts with minimal waste and faster turnaround times, significantly enhancing productivity and sustainability.

**Tips:** When considering the implementation of innovative technologies in parts manufacturing, start small with pilot projects. Testing new techniques on a limited scale can help identify potential challenges and fine-tune the process before a full-scale rollout. Additionally, investing in employee training for new technologies can ensure that your workforce is well-prepared to leverage these innovations effectively.

Moreover, the integration of real-time data analytics plays a crucial role in monitoring production processes and predicting maintenance needs. By harnessing data, manufacturers can optimize operations, reduce downtime, and make informed decisions swiftly.

**Tips:** Utilizing cloud-based platforms can offer seamless access to data and collaboration tools among teams. This not only enhances communication but also provides a comprehensive view of the manufacturing process, driving continuous improvement and innovation.

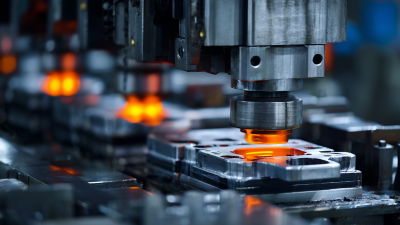

The advent of automation in parts manufacturing has dramatically transformed production processes across various industries. Automation technologies, including robotics, artificial intelligence, and machine learning, are enhancing production efficiency by streamlining operations and reducing human error. By taking over repetitive tasks, automated systems enable manufacturers to allocate their workforce to more complex and strategic roles, thereby increasing overall productivity and innovation.

Furthermore, automation allows for better quality control and consistency in production. Advanced sensors and real-time monitoring systems enable manufacturers to detect defects and inefficiencies instantly, allowing for timely interventions. This not only improves product quality but also minimizes waste, leading to cost savings and a more sustainable manufacturing process. As industries continue to embrace automation, the potential for further revolution in production efficiency remains vast, paving the way for a future where manufacturing is not only faster but also smarter.

Sustainable practices in parts manufacturing are increasingly becoming essential as industries pivot towards greener alternatives. By integrating eco-friendly materials and processes, manufacturers are not only reducing waste but also enhancing the lifecycle of their products. Techniques such as additive manufacturing and smart recycling methodologies allow companies to minimize resource consumption while maximizing efficiency. This shift not only addresses environmental concerns but also appeals to a growing demographic of environmentally-conscious consumers.

Moreover, embracing renewable energy sources for production facilities significantly lowers carbon footprints. Many companies are investing in solar or wind energy, which reduces reliance on fossil fuels. Additionally, implementing lean manufacturing principles helps eliminate excess materials and streamline operations, further contributing to sustainability goals. As parts manufacturing evolves, it plays a pivotal role in shaping a more sustainable industrial future, paving the way for innovations that prioritize ecological balance alongside economic growth.

The revolution in parts manufacturing is being driven by advancements in customizability and rapid prototyping, which are essential for modern industries striving to meet the evolving demands of consumers. The introduction of large-scale 3D printing farms has paved the way for mass customization, allowing manufacturers to produce tailored components quickly and efficiently. As technology progresses, the ability to create unique designs on-demand is becoming a vital asset, significantly reducing lead times and enhancing production flexibility.

Industries such as packaging, medical devices, and fashion are witnessing a paradigm shift due to these innovations. For instance, the rise of 3D printing in packaging is reshaping supply chains, enabling eco-friendly practices, and facilitating quick adaptations to market changes. Similarly, the medical device sector is experiencing robust growth, driven by customized manufacturing solutions that cater to specific patient needs. As companies embrace these technologies, the focus on sustainability and responsiveness will redefine their operations, ultimately leading to more resilient and dynamic manufacturing ecosystems.

Advanced parts manufacturing is transforming various industries, enabling businesses to innovate and enhance productivity. For instance, the automotive sector has seen significant advancements through 3D printing and additive manufacturing. Companies like Tesla are utilizing these technologies to produce complex components that were previously too costly or time-consuming to create. This has led to faster prototyping and reduced waste, showcasing how modern manufacturing techniques can drive efficiency and sustainability.

In the aerospace industry, firms such as Boeing have adopted advanced parts manufacturing methods to produce lightweight components that improve fuel efficiency. The ability to rapidly iterate designs and create customized parts has given manufacturers a competitive edge. Additionally, these innovations have facilitated the emergence of new materials, contributing to stronger and lighter aircraft structures.

**Tips:** To stay ahead in the evolving landscape of advanced parts manufacturing, businesses should invest in training for their workforce on new technologies. Emphasizing collaboration between engineering and production teams can also foster creativity and streamline operations, leading to more effective manufacturing solutions. Embracing an agile mindset will further allow companies to quickly adapt to industry changes and consumer demands.

| Industry | Technology Used | Benefits | Case Study Example |

|---|---|---|---|

| Automotive | 3D Printing | Reduced weight and cost of parts | Production of complex components |

| Aerospace | CNC Machining | Enhanced precision and durability | Lightweight structural components |

| Healthcare | Bioprinting | Customization of implants and prosthetics | Personalized treatment options |

| Consumer Electronics | Injection Molding | Mass production and cost efficiency | Enclosure designs for devices |

| Construction | Prefabrication | Faster project completion | Modular building solutions |