In the rapidly evolving landscape of manufacturing, optimizing manufacturing solutions is crucial for businesses aiming at efficiency and growth. According to the McKinsey Global Institute, productivity improvements in manufacturing could boost global GDP by $8 trillion by 2030. This staggering figure underscores the necessity for innovative approaches in manufacturing processes. Companies that adopt advanced manufacturing solutions are not only keeping pace but often surpassing their competitors in both profitability and market share.

James Morgan, a leading expert in the manufacturing sector, states, "Streamlined processes and smart technologies are the backbone of tomorrow’s manufacturing." His words remind us of the imperative to leverage data analytics, automation, and lean manufacturing techniques. However, several companies still grapple with outdated practices that hinder progress. Many organizations find it challenging to integrate new technologies into their existing workflows while maintaining output quality. Such barriers often lead to inefficiencies and missed opportunities for growth.

As manufacturers face labor shortages and rising costs, the urgency to refine existing manufacturing solutions is more pressing than ever. A recent report by Deloitte highlighted that 55% of manufacturers struggle with scalability. This statistic reflects a broader need to rethink strategies for optimizing production capabilities. Embracing change is essential, yet the execution often entails reflections on past practices and a willingness to adapt.

In 2026, the importance of manufacturing solutions cannot be overstated. Companies face increased pressure to enhance efficiency while promoting growth. Effective solutions can streamline workflows and reduce costs. However, many organizations still struggle with outdated processes. This gap highlights the need for continuous improvement and adaptability.

Tip: Regularly assess your current manufacturing processes. Identify bottlenecks and areas needing improvement. Innovation is key, but the implementation can be quite challenging. Often, resources are limited, and time constraints add pressure. This leads to hasty decisions that may not yield the best results.

Investing in training for staff can also enhance productivity. An informed workforce is more capable of optimizing operations. Workers should understand their roles within the larger picture. Yet, companies sometimes underestimate the value of ongoing education. They risk falling behind competitors who prioritize skill development.

Tip: Foster a culture that encourages questions and feedback. Open dialogue can uncover hidden issues. Embrace imperfections and learn from them. Growth comes from addressing weaknesses and striving for better solutions.

Optimizing manufacturing processes can lead to significant growth. Efficiency is key. One effective strategy is to implement lean manufacturing principles. This involves eliminating waste from every aspect of production. Analyze each step carefully. Identify what adds value and what does not. For example, excess inventory or prolonged setup times can be detrimental.

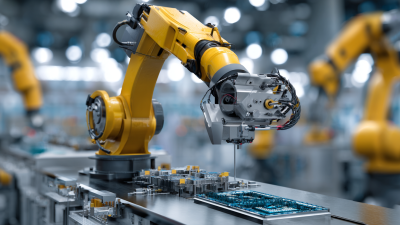

Another crucial strategy is embracing technology. Automation can streamline production lines. It reduces human error and accelerates processes. However, integrating new tech may face resistance from employees. Training is essential to ease this transition. Regular feedback should also be sought to refine processes continuously.

Lastly, fostering a culture of continuous improvement is vital. Encourage workers to suggest ideas. They often see inefficiencies that managers may overlook. Yet, not every suggestion will lead to improvement. It’s essential to reflect on what works and what doesn’t. Embracing both success and failure drives growth.

The landscape of manufacturing is rapidly changing. Technology plays a significant role in increasing efficiency. Automation tools help to streamline production processes. They reduce downtime and enhance output. However, adopting new technology isn't without challenges. Many manufacturers struggle to integrate these solutions effectively.

Data analytics can provide valuable insights. It allows businesses to track performance metrics in real-time. Yet, some companies find it difficult to interpret this data. They may not see the immediate benefits. A lack of training can hinder adoption. It's crucial for teams to understand how technology applies to their roles.

Investing in the right systems can lead to substantial growth. Augmented reality and IoT devices create vivid communication channels. They can enhance collaboration between teams. However, companies must be cautious. Over-reliance on technology may create vulnerabilities. Balancing human and machine elements is key.

Implementing lean principles can significantly enhance manufacturing efficiency. This approach minimizes waste and maximizes value. By streamlining operations, manufacturers can focus on what truly matters: producing quality products. Tools like Value Stream Mapping help identify areas of inefficiency. It’s not always easy to implement these changes. Workers may resist new processes, leading to initial disruptions.

Training staff on lean methods is essential. However, the learning curve can be steep. Mistakes will happen, and that's part of the journey. Encouraging feedback helps create a culture of continuous improvement. Sometimes, teams may overlook small inefficiencies that add up. Regularly reviewing processes can reveal insights that drive further optimization.

Communication throughout the organization is key to success. Everyone must understand lean principles and their importance. It's common for not all team members to buy into these changes. Understanding their concerns can lead to better implementation strategies. Together, these actions create a more efficient manufacturing environment, facilitating growth and sustainability.

| Dimension | Current Status | Target Status | Improvement Strategy |

|---|---|---|---|

| Production Lead Time | 14 days | 7 days | Implement Just-In-Time (JIT) inventory management |

| Defect Rate | 5% | 1% | Adopt Total Quality Management (TQM) practices |

| Machine Utilization Rate | 70% | 85% | Conduct regular maintenance and optimize scheduling |

| Employee Productivity | 80 units/day | 150 units/day | Implement training programs and incentive plans |

| Overall Equipment Effectiveness (OEE) | 60% | 90% | Use Lean manufacturing techniques to identify waste |

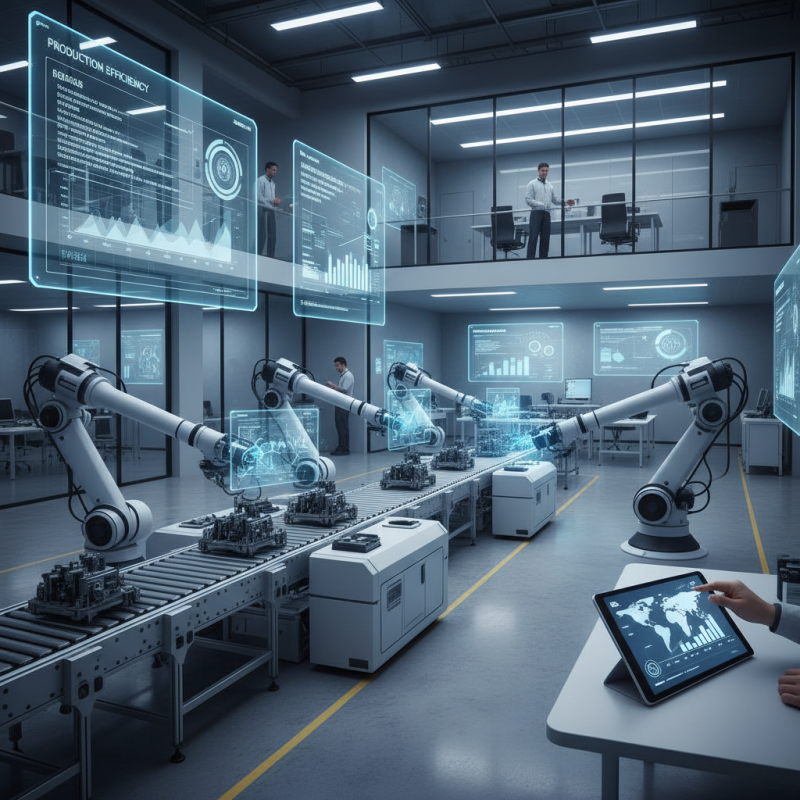

In today's competitive landscape, measuring success in manufacturing optimization is crucial. Key Performance Indicators (KPIs) provide a structured way to evaluate efficiency. Common KPIs include Overall Equipment Effectiveness (OEE) and production cycle time. These metrics reveal bottlenecks in processes, yet they often overlook employee engagement.

It's not just about numbers; the human element matters. High turnover rates can impact production. A KPI that tracks employee satisfaction could complement traditional metrics. This approach brings a holistic view to optimization. Companies must ask, are we listening to our workforce? Are we fostering an environment of innovation?

Additionally, focusing solely on output may lead to shortcuts. This practice can compromise quality. Monitoring defects per million opportunities (DPMO) alongside output levels can help maintain standards. Balancing speed with quality should be a priority. Optimization is not always about being the fastest. Sometimes, it’s about being the smartest.