In modern manufacturing, machined steel parts play a pivotal role. These components provide strength, durability, and precision. Their versatility makes them essential for various industries, from automotive to aerospace.

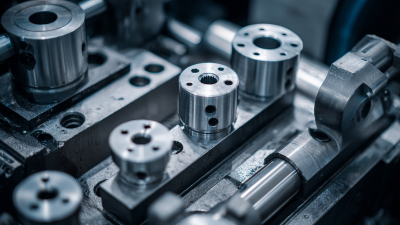

The production process behind machined steel parts involves intricate techniques. CNC machining allows for remarkable accuracy, shaping raw steel into functional pieces. However, challenges remain. Not every manufacturer achieves the same level of precision. Some errors can lead to significant setbacks in production timelines.

Despite these concerns, the advantages of machined steel parts are undeniable. They withstand extreme conditions and offer reliable performance. As technology evolves, the demand for better quality continues to grow. Manufacturers must adapt and improve their processes to meet these expectations. Reflecting on these aspects helps us appreciate the true value of machined steel parts in our economy and daily lives.

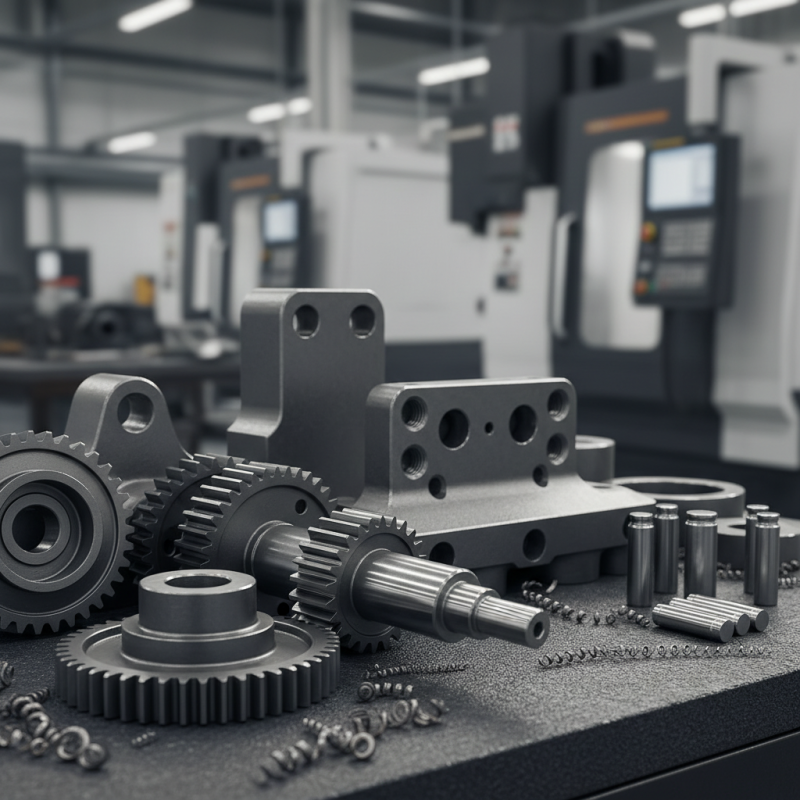

Machined steel parts play a crucial role in modern industrial processes. They are used across various sectors, including automotive, aerospace, and manufacturing. According to a recent report by the International Federation of Robotics, approximately 1.7 million industrial robots are in operation worldwide. These robots often rely on precision machined steel parts for efficiency.

High strength and durability are key advantages of machined steel. Parts made from steel can withstand heavy loads and harsh environments. For instance, components in aircraft engines are subjected to extreme temperatures and pressure. Machined steel can handle these demands without failure. However, the machining process can be wasteful. Up to 30% of raw material can be lost during fabrication.

Tips: Always assess the machining process. Look for methods to reduce waste. Explore newer technologies for greater efficiency.

Quality control is another essential factor. Parts must meet strict specifications. A 2020 study highlighted that 20% of manufacturing defects come from poor machining practices. This issue emphasizes the need for precise techniques and inspection methods. Manufacturers must continually adapt to maintain quality.

Tips: Implement regular checks on machined parts. Invest in employee training to improve skills. Adapt processes based on feedback from quality assessments.

Machined steel components play a crucial role in modern manufacturing. Their strength and precision contribute significantly to product quality. According to a recent industry report, over 50% of precision-engineered parts are made from steel. This number highlights the material's dominance in manufacturing processes.

One key advantage of machined steel is its durability. Steel parts withstand extreme conditions, from high temperatures to heavy loads. This reliability leads to longer product lifespan. For example, automotive applications extensively use machined steel. The reports indicate that vehicles with steel components can last up to 15% longer than those using alternative materials. However, not all manufacturers exploit this potential. Some still rely on less durable materials, risking product failure.

Precision in machining is another significant benefit. Steel can be processed to incredibly tight tolerances. This feature reduces the likelihood of assembly issues. Research shows that companies that prioritize precision machining have a 30% lower defect rate. Nevertheless, achieving such precision requires advanced technology and skilled workers, which can be a barrier for some businesses. Balancing cost and quality remains a challenge in the industry today.

Machined steel parts play a crucial role across various industries. In the automotive sector, these components ensure precision and reliability. Engine blocks and pistons are often made from high-quality machined steel. They withstand high temperatures and pressure, making them essential for performance. Each part must fit perfectly; otherwise, inefficiency occurs.

In the aerospace field, machined steel components are critical for safety. Parts like landing gear and structural components must endure extreme conditions. Any slight imperfection can lead to catastrophic failures. The manufacturing process involves intricate designs and tolerances that require attention to detail. Miscalculations here can have serious repercussions.

Manufacturers face challenges in balancing cost and quality. While machined steel parts are durable, they are often expensive. This raises questions about sustainability and long-term use. Many companies are exploring alternative materials, but steel remains the favorite for strength. Adapting to new technologies could redefine how these parts are made in the future.

Technological innovations in machining steel have revolutionized the manufacturing landscape. Advanced techniques like CNC machining offer precision and speed. Automation plays a key role in reducing human error. As manufacturers adopt these technologies, efficiency skyrockets. This shift allows for high-quality parts produced in shorter time frames. The integration of AI and machine learning enhances process optimization.

While these advancements bring significant benefits, there are challenges to consider. The initial investment for new machinery can be steep. Not every facility is equipped to handle such technologies. Additionally, training staff to utilize these advancements effectively is crucial. Without proper knowledge, even top-notch equipment may underperform. There remains a continuous need for skills development in this evolving field.

Furthermore, sustainability is a pressing issue in modern machining. As we push for efficiency, waste management and energy consumption should not be overlooked. Adopting eco-friendly practices is essential, yet many companies struggle to implement them effectively. It's an ongoing journey towards finding a balance between innovation and responsibility.

Machined steel parts play a critical role in modern manufacturing. Their sustainability greatly impacts production efficiency. According to a report from the World Steel Association, steel is 100% recyclable. This aspect lowers the demand for raw materials and reduces waste. Factories that use machined steel often report reduced energy consumption. The production of machined steel parts can be 30% more efficient compared to alternatives.

Cost-effectiveness is another key factor. A study by the Metalworking Industry Association stated that using machined steel can save up to 20% in production costs. These savings come from lower maintenance and longer-lasting components. However, it's also essential to consider the upfront costs of machinery and skilled labor. These factors can add unpredictability to budgeting.

Sustainability and cost-effectiveness are interconnected. While machined steel parts offer benefits, the manufacturing process still generates emissions. Striking the right balance between innovation and sustainable practices can be challenging. Manufacturers must continually evaluate their processes. It's crucial to adopt practices that not only focus on immediate profits but also consider long-term impacts on the environment.