In the ever-evolving landscape of industrial production, the realm of modern manufacturing stands at the forefront, driven by technological advancements that promise to reshape our capabilities and efficiencies. As we delve into the future of modern manufacturing technology, it is essential to recognize the insights of industry experts who have dedicated their careers to understanding these transformations. Dr. Amelia Hart, a leading figure in manufacturing innovation, asserts,

"The future of modern manufacturing lies in our ability to integrate intelligent systems and sustainable practices that not only enhance productivity but also ensure environmental responsibility."

As we explore the top ten trends poised to influence the modern manufacturing industry, it becomes clear that the integration of automation, artificial intelligence, and sustainable materials will redefine traditional manufacturing paradigms. The convergence of these technologies is not merely about increasing output; it's about creating smarter, more agile manufacturing environments that can swiftly adapt to changing market demands. Moreover, the emphasis on sustainability reflects a growing awareness in the industry of the need to balance economic growth with ecological preservation.

Through this outline, we will examine how these innovations will not only improve operational efficiency but also foster a new era of collaboration and ingenuity across sectors. The future of modern manufacturing is not just an objective; it's a shared journey towards a more connected and responsible industrial ecosystem.

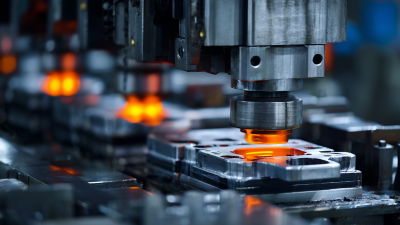

As automation and robotics continue to gain momentum, the manufacturing industry is witnessing a transformative shift. The industrial robotics market is projected to soar, reaching a staggering USD 291.1 billion by 2035. This growth indicates a significant adoption of AI-powered robots, which are revolutionizing production processes and enhancing efficiency in various sectors. Companies are increasingly integrating these technologies, leading to improved precision, productivity, and competitive advantage.

Tips: When considering the incorporation of robotics into your manufacturing processes, assess your current operational needs and identify areas where automation can enhance performance. Engaging with technology experts can provide insights into potential integrations that align with your business strategy.

The impact of AI-driven automation extends beyond mere productivity gains. Recent developments show that these technologies can mitigate labor displacement in regions such as East Asia and the Pacific, as they bolster employment through increased productivity and scale. Furthermore, autonomous robots are redefining supply chain dynamics, significantly lowering long-term costs for manufacturers. As these trends unfold, the future of manufacturing will increasingly harmonize human talent and automation, creating a more efficient and resilient industry landscape.

Tips: Stay updated on advancements in robotic technologies and consider developing a workforce skilled in both human oversight and technology operation to ensure a balanced integration in your manufacturing setup.

The advancements in 3D printing technology are revolutionizing the manufacturing landscape, offering unprecedented opportunities for efficiency and customization. According to the Wohlers Report 2021, the additive manufacturing industry is projected to grow to $35.6 billion by 2024, driven by innovations that significantly reduce production time while enabling complex designs that were previously impossible. Companies are increasingly adopting 3D printing not just for prototyping but for end-use parts, showcasing a shift towards more flexible manufacturing processes that can respond rapidly to market demands.

Tips: When considering 3D printing for your production lines, assess the materials best suited for your products to maximize quality and performance. Investing in employee training on new technologies can also enhance the adoption process and ensure that your team can leverage these advanced tools effectively.

The transformative effects of 3D printing extend beyond cost savings and efficiency; they also facilitate sustainability efforts. A study by McKinsey & Company highlighted that 3D printing can reduce waste in manufacturing by up to 70%, as it enables precise material usage. This aligns perfectly with modern industry's move towards environmental responsibility, making 3D printing not just a technological innovation but a key strategy in sustainable manufacturing practices.

Tips: Evaluate your supply chain to identify areas where 3D printing can replace traditional methods, potentially reducing lead times and material waste. Collaborating with experts in additive manufacturing can help refine your approach to implementing these technologies effectively.

| Dimension | Description | Impact on Industry | Future Trends |

|---|---|---|---|

| Additive Manufacturing | A process of creating objects layer by layer from 3D models. | Reduces material waste and increases design flexibility. | Emergence of more sustainable materials and faster printing technologies. |

| Customization | Tailoring products to meet specific customer needs. | Enhances user satisfaction and can lead to higher sales. | Greater integration of artificial intelligence into design processes. |

| Supply Chain Optimization | The use of technology to streamline supply chain processes. | Improves efficiency and reduces costs. | Increased use of blockchain for transparency and traceability. |

| Rapid Prototyping | Quickly building a scale model of a physical part. | Speeds up the design process and innovation timeline. | Integration with virtual reality for better visualization. |

| Industrial IoT | Network of interconnected devices that monitor and manage manufacturing processes. | Enables real-time data analysis and predictive maintenance. | Increased focus on cybersecurity measures and protocols. |

The rise of smart factories is revolutionizing the manufacturing sector through the integration of the Internet of Things (IoT). By 2025, the global market for wireless industrial IoT sensors is projected to reach approximately $7.973 billion, with an impressive growth forecast of reaching $21.498 billion by 2033, reflecting a compound annual growth rate (CAGR) of 13.2%. This surge is indicative of the industry's shift towards smarter, data-driven operations that enhance efficiency and adaptability in manufacturing processes.

Additionally, advancements in artificial intelligence are pivotal to the transformation of the manufacturing landscape. The global market for AI in manufacturing is expected to soar from $760 billion in 2025 to a staggering $623.3 billion by 2032, achieving a staggering CAGR of 35.1%. These technologies are not only streamlining production but also enabling predictive maintenance and optimizing supply chains, positioning manufacturers to better respond to fluctuating market demands. With the unveiling of 5G-Advanced technologies, the future of industrial connectivity promises an even more integrated approach, fostering a truly interconnected environment across various manufacturing sectors.

The integration of sustainable manufacturing technologies is revolutionizing the industrial sector, heralding a new era that emphasizes eco-friendliness alongside efficiency. According to a report by the World Economic Forum, the adoption of sustainable practices can reduce production costs by up to 30% while simultaneously cutting greenhouse gas emissions significantly. As industries race to align with stringent regulations and consumer preferences for greener products, the implementation of advanced technologies, such as 3D printing and renewable energy systems, has become crucial. These innovations not only facilitate waste reduction but also optimize resource utilization, creating a more circulatory economy.

Moreover, a study by McKinsey indicates that companies embracing sustainability in manufacturing can enhance their operational resilience and competitive advantage. For instance, businesses leveraging smart manufacturing systems report a 25% increase in productivity and a substantial reduction in material waste. As organizations commit to sustainability, the emphasis on adopting technologies that promote energy efficiency and decrease carbon footprints will play a pivotal role in shaping a greener industry. This transformation is not just a trend but a necessary evolution, positioning companies to thrive in an increasingly environmentally-conscious market.

In recent years, the integration of Artificial Intelligence (AI) with digital twin technology has emerged as a pivotal driver for market growth in modern manufacturing. Enhanced simulation design and high-resolution modeling offered by digital twins enable precise manufacturing processes to become more feasible. For instance, the textile industry, particularly exemplified by developments in Jilin Chemical Fiber Group’s artificial silk production, showcases how robotic arms can efficiently stack finished silk spools, underscoring the intersection of advanced technologies and traditional crafting methods. According to McKinsey’s report, industrial automation spending is highest in process industries, confirming that automated processes are becoming increasingly vital for maintaining productivity.

The implications of AI in manufacturing extend beyond robotic enhancements to include smart textiles, which signify a transformative approach to product design and functionality. As these technologies evolve, industries are aligning their operations with national policies promoting innovation, leading to a steady increase in the production of major textile products in the first half of this year. Additionally, AI’s evolution into a strategic driver of change is evident as it facilitates a shift toward intelligent production systems, thereby reshaping management practices and fostering innovation in service delivery. This synergy between AI and the digital twin paradigm marks a significant step toward revolutionizing modern manufacturing landscapes.