The manufacturing sector is undergoing a significant transformation, driven by technological advancements and the increasing demand for efficiency and precision. Among these innovations, the steel stamping machine stands out as a critical tool in modern manufacturing processes. According to a recent report by Allied Market Research, the global stamping machine market is projected to reach $12.93 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.3% from 2020. This growth is largely fueled by the rise in automotive and aerospace production, where steel stamping machines play an essential role in producing complex components with high durability and accuracy. As manufacturers seek to enhance productivity and reduce waste, innovations in steel stamping technology, including automation and advanced materials integration, are set to redefine the landscape of the manufacturing industry, ensuring that companies remain competitive in an ever-evolving market.

The landscape of manufacturing is evolving, particularly in the realm of steel stamping technology, where innovations are reshaping production processes. According to a recent report by Technavio, the global steel stamping market is expected to grow at a CAGR of over 5% from 2021 to 2025. This growth is being driven by advancements in automation and the integration of smart technologies into traditional manufacturing setups. The adoption of Industry 4.0 principles, including the Internet of Things (IoT) and artificial intelligence (AI), is enabling manufacturers to optimize their operations, reduce waste, and enhance product quality.

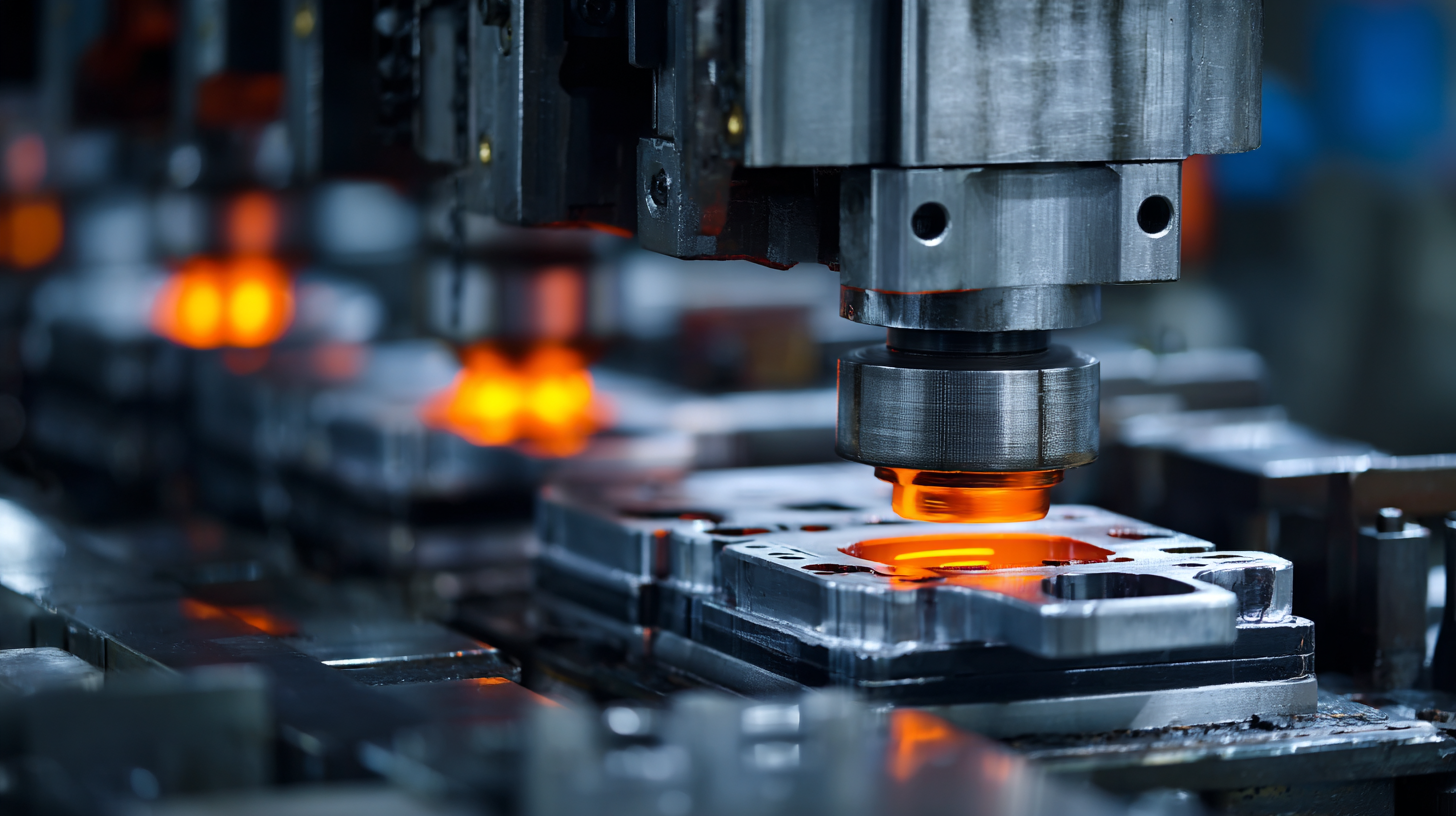

One notable trend in steel stamping innovations is the shift towards using advanced materials and coatings that improve durability and performance. For example, lighter and stronger alloys are becoming increasingly popular, offering better mechanical properties while also reducing overall weight. Additionally, new stamping techniques, such as progressive die stamping and tandem stamping, are being adopted to enhance efficiency and precision. According to a report by Market Research Future, the introduction of these technologies could increase production rates by as much as 30%, providing manufacturers with the competitive edge needed in today’s demanding market.

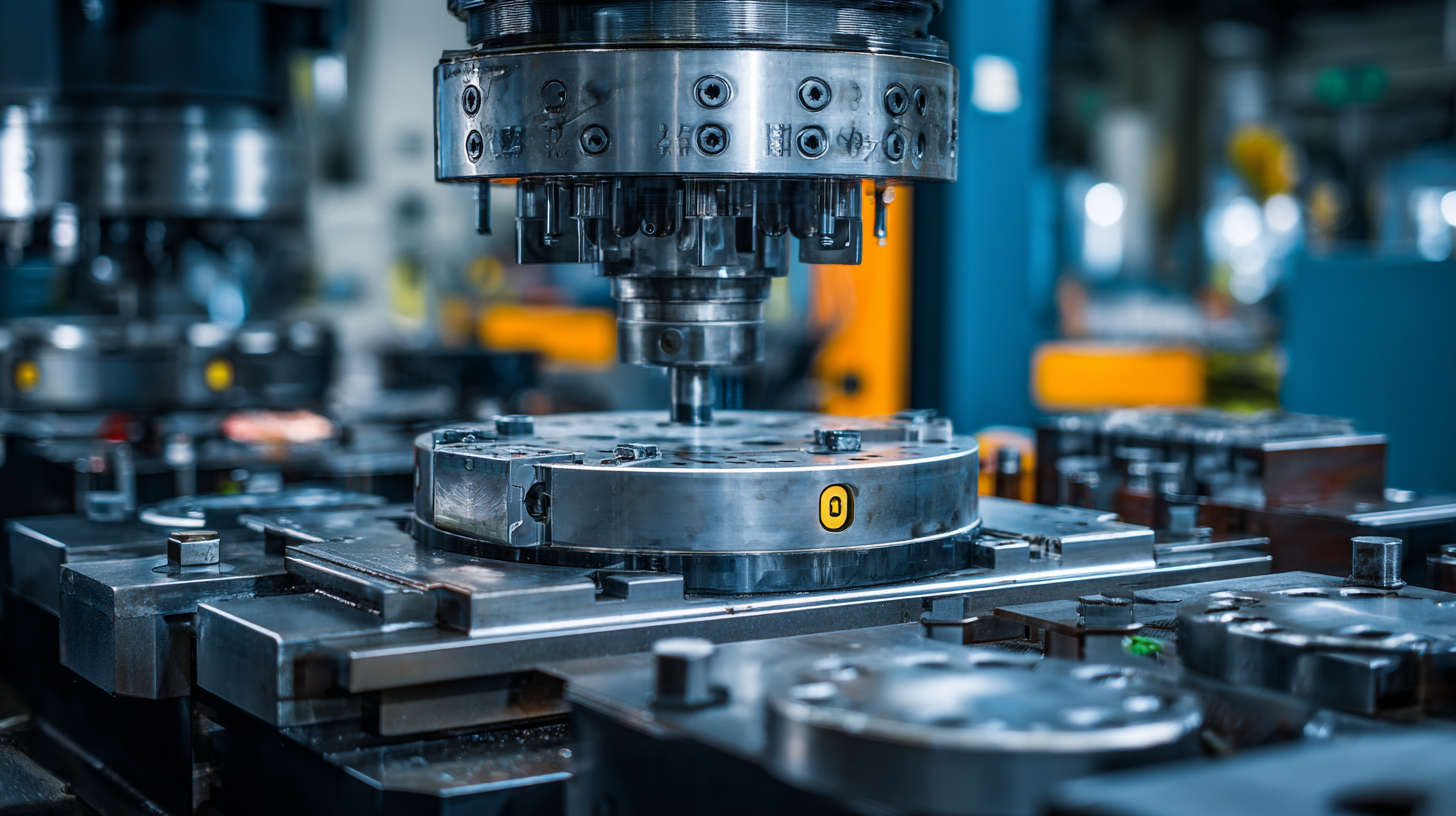

When selecting a steel stamping machine, several key features should be prioritized to ensure optimal performance and efficiency. First and foremost, the machine's capacity to handle different material thicknesses is crucial. A versatile machine that accommodates a range of steel gauges can significantly enhance production flexibility, allowing manufacturers to adapt to varying project requirements without the need for multiple machines.

Another important aspect to consider is the speed and precision of the stamping process. Advanced machines equipped with servo-driven technologies can provide higher speed and accuracy in producing complex shapes. This not only improves the quality of the finished products but also increases overall production rates, reducing lead times. Additionally, ease of maintenance and availability of parts are vital factors. A machine designed for straightforward maintenance can minimize downtime and ensure continuous operation, contributing to a more efficient manufacturing workflow.

The role of automation in modern steel stamping processes has become increasingly vital as manufacturers strive for efficiency and precision. According to a recent report by MarketsandMarkets, the global automation market in the manufacturing sector is expected to reach $300 billion by 2025, emphasizing the pivotal shift towards automated systems. This transformation enables steel stamping operations to enhance productivity by reducing cycle times and minimizing human error.

One significant advancement in automation is the integration of robotics and artificial intelligence in stamping machines. These technologies allow for real-time monitoring and optimization of the stamping process, leading to reduced waste and improved product quality. A study from Deloitte indicates that companies utilizing advanced manufacturing technologies, including automation, can achieve productivity gains of up to 30%. Furthermore, the implementation of automation not only enhances operational efficiency but also addresses the growing skills gap in the workforce, enabling companies to maintain a competitive edge in the global market.

Sustainability has become a crucial consideration in the manufacturing sector, particularly in the steel stamping industry. According to a recent report by the World Steel Association, the steel industry accounts for approximately 7% of global carbon emissions. In response, many manufacturers are adopting innovative practices to reduce their environmental footprint. For instance, implementing energy-efficient machinery and transitioning to eco-friendly materials can significantly lower emissions during the stamping process. Advanced steel stamping machines equipped with energy recovery systems can reduce energy consumption by up to 30%, proving that sustainability and efficiency can go hand in hand.

Furthermore, the integration of circular economy practices is gaining traction within the steel stamping landscape. Research from McKinsey & Company highlights that reusing scrap metal and optimizing production processes can lead to substantial resource savings, potentially cutting costs by 20-30%. By repurposing scrap steel, manufacturers not only minimize waste but also reduce their dependency on virgin materials, which are energy-intensive to produce. Such strategies reflect a growing trend toward sustainable manufacturing that prioritizes both ecological responsibility and economic viability, highlighting a promising future for innovations in steel stamping machinery.

The steel stamping industry is poised at a critical juncture, facing both challenges and opportunities that will shape its future. One of the primary challenges is the increasing demand for customization, which necessitates the development of more flexible and efficient stamping processes. Manufacturers must invest in advanced technologies such as automation and smart manufacturing to meet these changing customer needs while maintaining profitability. As competition intensifies globally, companies must also address the issue of sustainable practices, balancing environmental considerations with operational efficiency.

On the horizon, the opportunities for innovation are vast. The integration of artificial intelligence and machine learning into steel stamping processes can significantly enhance productivity and quality by enabling predictive maintenance and real-time monitoring. Additionally, advancements in materials science may lead to lighter and stronger steel formulations, further pushing the boundaries of what stamped products can achieve. Embracing these innovations not only positions firms to capitalize on emerging market trends but also empowers them to overcome existing challenges, ensuring a resilient and forward-looking steel stamping industry.

| Innovation Type | Current Applications | Future Challenges | Opportunities |

|---|---|---|---|

| Automated Steel Stamping | Automotive Parts Manufacturing | High Initial Investment | Increased Production Efficiency |

| 3D Printing Integration | Prototype Development | Material Compatibility | Custom Parts Production |

| Smart Sensors | Machine Monitoring | Data Security | Predictive Maintenance |

| Eco-friendly Materials | Sustainable Fabrication | Regulatory Compliance | Market Differentiation |

| Artificial Intelligence | Design Optimization | Integration with Legacy Systems | Enhanced Decision-Making |