The aluminum parts manufacturing industry is undergoing a transformative shift, driven by advancements in technology and a growing emphasis on sustainability. According to a recent report by the International Aluminum Institute, global aluminum demand is projected to increase by 40% by 2030, underscoring the material's critical role in various sectors, including automotive and aerospace. This surge is complemented by a progressive trend towards sustainable engineering practices, as manufacturers seek to reduce their carbon footprint and improve resource efficiency.

Innovations in additive manufacturing and recycling processes are enabling the production of lightweight aluminum components that not only meet contemporary performance standards but also adhere to the principles of circular economy. As the industry evolves, understanding the interplay between aluminum parts manufacturing and sustainable practices becomes essential for stakeholders aiming to navigate the challenges of the future while contributing to environmental preservation.

The role of aluminum in sustainable manufacturing practices is becoming increasingly significant as industries strive for greener solutions amidst global uncertainties. According to recent industry reports, aluminum production has seen a shift towards more sustainable methods, with an estimated reduction of carbon emissions by up to 30% in the last decade due to advancements in recycling technologies and the adoption of renewable energy sources. This aligns with the growing commitment of manufacturers to integrate sustainable practices into their operations, responding to both consumer demand and regulatory pressures.

Furthermore, the expansion of the green finance market is supporting sustainable initiatives in the aluminum sector. Recent developments highlight the launch of sustainability-linked financing products tailored specifically for the aluminum industry, encouraging companies to adopt eco-friendly practices. With the global aluminum market projected to reach nearly $200 billion by 2026, investing in sustainable production methods is not just beneficial for the environment but also crucial for long-term economic resilience. The interplay between financial incentives and innovative manufacturing processes can accelerate the transition to a more sustainable future in aluminum parts manufacturing.

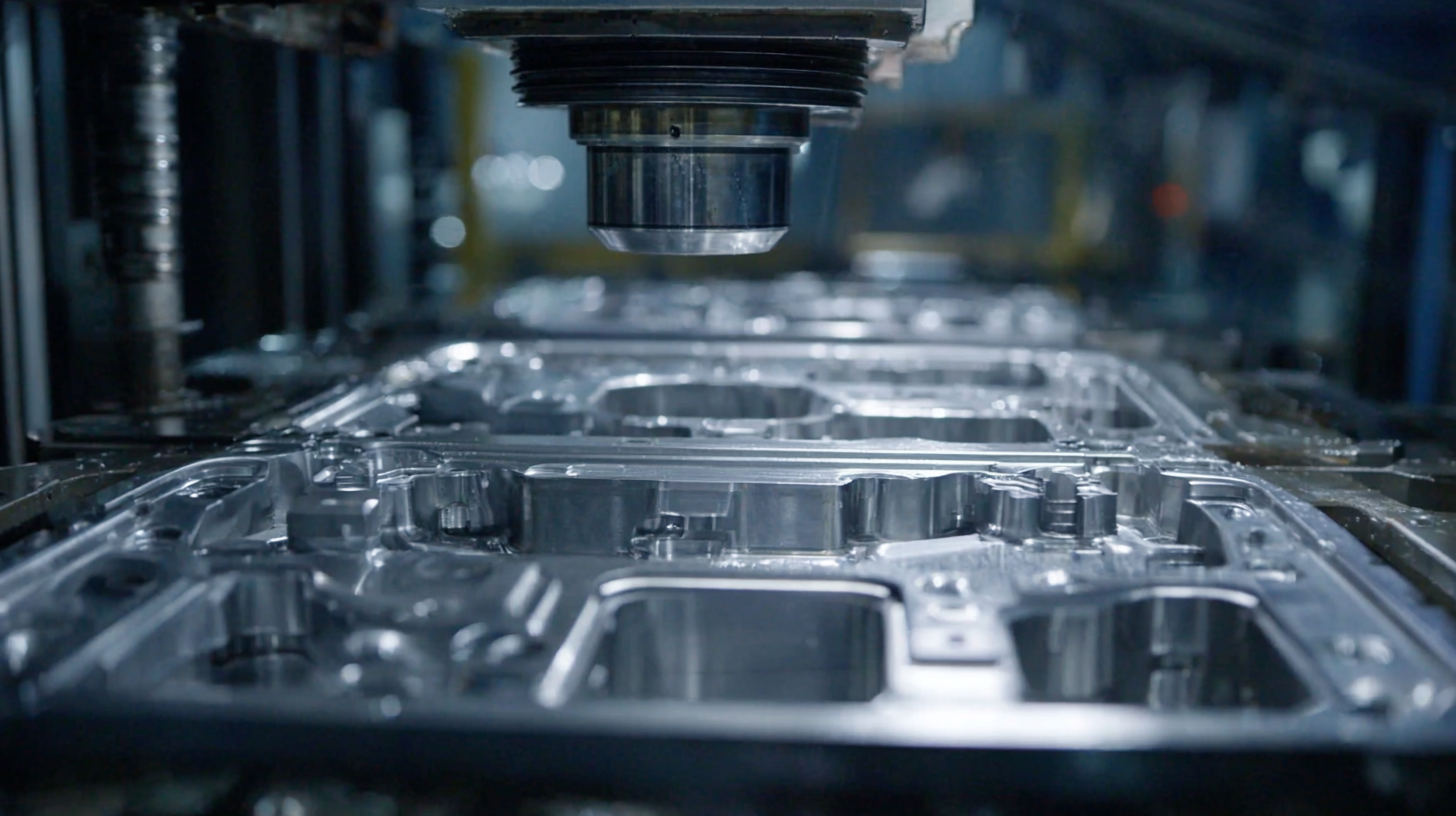

Innovative technologies are reshaping the aluminum parts manufacturing landscape, driving advancements that prioritize sustainability and efficiency. The shift towards advanced bauxite mining innovations is set to redefine the industry, as it is projected that over 60% of global aluminum production in 2025 will incorporate these sustainable practices. This focus on environmentally friendly extraction methods not only enhances production capabilities but also contributes to the overall reduction of the carbon footprint associated with aluminum manufacturing.

In addition to mining innovations, breakthrough techniques such as shear-assisted processing and solid-phase alloying are revolutionizing production methods. These processes not only lower manufacturing costs but also enhance the quality of raw materials while significantly reducing energy consumption and emissions. Furthermore, advancements in laser welding technology allow for the intelligent and sustainable joining of different materials, showcasing the industry's commitment to integrating innovative solutions that align with global sustainability goals. As the aluminum sector continues to evolve, these transformative technologies are poised to play a crucial role in shaping a more sustainable future for manufacturing.

The environmental benefits of aluminum compared to traditional materials such as steel or plastic are significant, making it a strong candidate for sustainable engineering practices. Aluminum is lightweight and has a high strength-to-weight ratio, which reduces energy consumption during transportation and improves fuel efficiency in vehicles and aircraft. Moreover, its durability and resistance to corrosion mean that aluminum products can have a longer lifespan, thereby reducing the need for frequent replacements and conserving resources.

In addition to its physical advantages, aluminum is highly recyclable, with up to 75% of all aluminum produced still in use today. The recycling process requires only 5% of the energy needed to produce new aluminum from ore, resulting in a substantial decrease in greenhouse gas emissions. By choosing aluminum over traditional materials, manufacturers can significantly lower their carbon footprint, promoting a circular economy. As industries increasingly seek to adopt sustainable practices, aluminum's environmental benefits position it as a key material in the future of manufacturing.

| Material Type | Recyclability (%) | Energy Input (MJ/kg) | Carbon Footprint (kg CO2/kg) | Common Applications |

|---|---|---|---|---|

| Aluminum | 100 | 200 | 3.3 | Automotive, Aerospace, Packaging |

| Steel | 74 | 30 | 1.8 | Construction, Automotive |

| Copper | 90 | 80 | 3.5 | Electrical, Plumbing |

| Plastic | 30 | 60 | 6.0 | Packaging, Consumer Goods |

As the demand for aluminum parts continues to rise, challenges in aluminum recycling remain a significant concern for sustainable engineering. According to the International Aluminum Institute, about 75% of all aluminum ever produced is still in use today, which highlights its potential for recycling. However, the recycling process is not without obstacles. Contaminants and alloys complicate the recycling stream, and insufficient infrastructure can hinder efficient recycling efforts.

To address these challenges, innovative solutions are emerging in the industry. Advanced sorting technologies, such as automated optical sorting and AI-based systems, have the potential to improve the purity of recycled aluminum. Furthermore, companies are investing in closed-loop recycling systems, which not only enhance recovery rates but also reduce the carbon footprint associated with aluminum manufacturing.

Reports from the European Aluminium Association indicate that a shift towards circular economy practices could lead to a 45% reduction in greenhouse gas emissions by 2030 in the aluminum sector. These advancements in recycling techniques are essential for ensuring a sustainable future for aluminum parts manufacturing.

The integration of circular economy principles in aluminum manufacturing is pivotal for fostering sustainable engineering practices. By emphasizing resource efficiency and waste reduction, the aluminum industry can significantly minimize its environmental footprint. This approach involves rethinking traditional linear production models, where materials are used and discarded, and instead developing systems that allow for the continuous reuse and recycling of aluminum. Utilizing recycled aluminum not only reduces energy consumption but also lowers emissions associated with the extraction and processing of raw materials.

Furthermore, adopting circular economy principles encourages innovation in manufacturing processes. Companies can invest in advanced technologies such as closed-loop systems, which facilitate the recovery of aluminum products at the end of their lifecycle. This not only leads to cost savings but also enhances the overall resilience of supply chains. Ultimately, by integrating these sustainable practices, the aluminum sector can play a crucial role in addressing global challenges such as resource scarcity and climate change, paving the way for a more sustainable future in manufacturing.

This chart illustrates the projected growth of recycled aluminum usage in manufacturing over the next decade, highlighting the shift towards sustainable engineering practices and integrating circular economy principles.