In the rapidly evolving landscape of modern manufacturing, innovations play a pivotal role in shaping efficiency and productivity. According to a recent report by McKinsey & Company, companies that embrace advanced technologies can increase productivity by up to 30%. This statistic highlights the transformative potential of modern manufacturing practices.

Renowned expert Dr. Emily Wang, a leader in manufacturing technology, emphasizes, “The future of manufacturing lies in our ability to integrate smart technologies effectively.” As industries strive to stay competitive, the incorporation of automation, AI, and IoT is becoming crucial. However, challenges remain. Many companies struggle to adapt their workforce to these new technologies, leading to gaps in skills and knowledge.

Moreover, the focus on sustainability is also influencing innovations in the sector. A 2022 study by Deloitte found that over 70% of manufacturers are prioritizing eco-friendly processes. Yet, some businesses continue to rely on outdated practices, causing inefficiencies. This tension between innovation and tradition is a key theme as we explore the best modern manufacturing innovations of 2026.

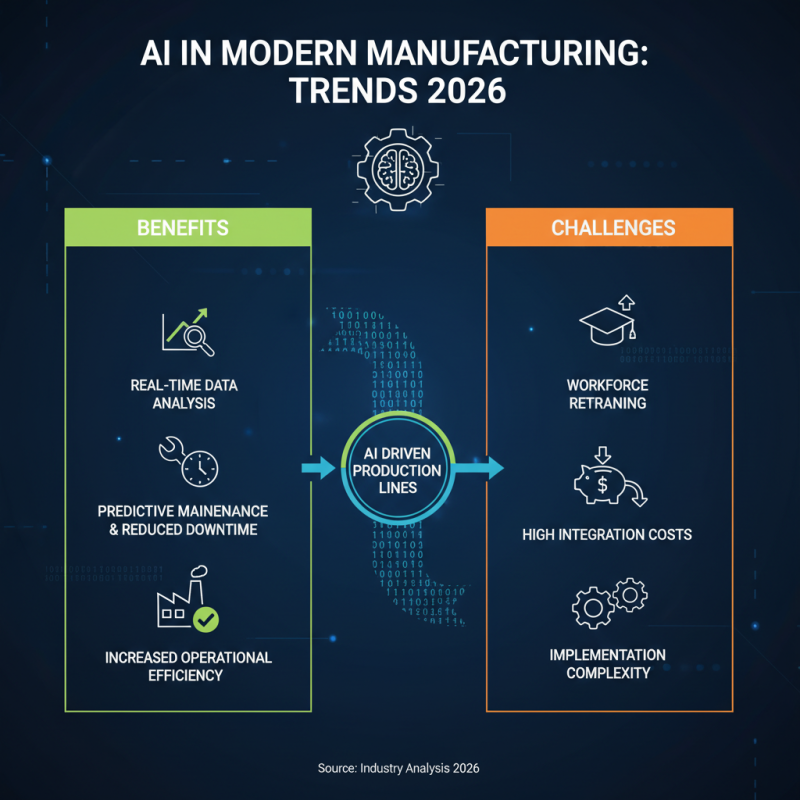

Modern manufacturing is evolving rapidly, driven by innovative technologies. One of the key trends for 2026 is the integration of artificial intelligence (AI) in production lines. AI can analyze data in real time. It helps in predictive maintenance, reducing downtime. Factories equipped with AI can often operate more efficiently. However, implementing AI presents challenges. Workforce retraining and integration costs can be high.

Another trend is the rise of sustainable manufacturing practices. Companies are focusing on eco-friendly materials and energy-efficient processes. This shift meets consumer demand for responsible production. Waste reduction techniques are becoming critical. Many organizations are still figuring out the best ways to implement these methods effectively. Transitioning to sustainability is not just about reducing impact; it’s a complex journey that demands consistent effort and evaluation.

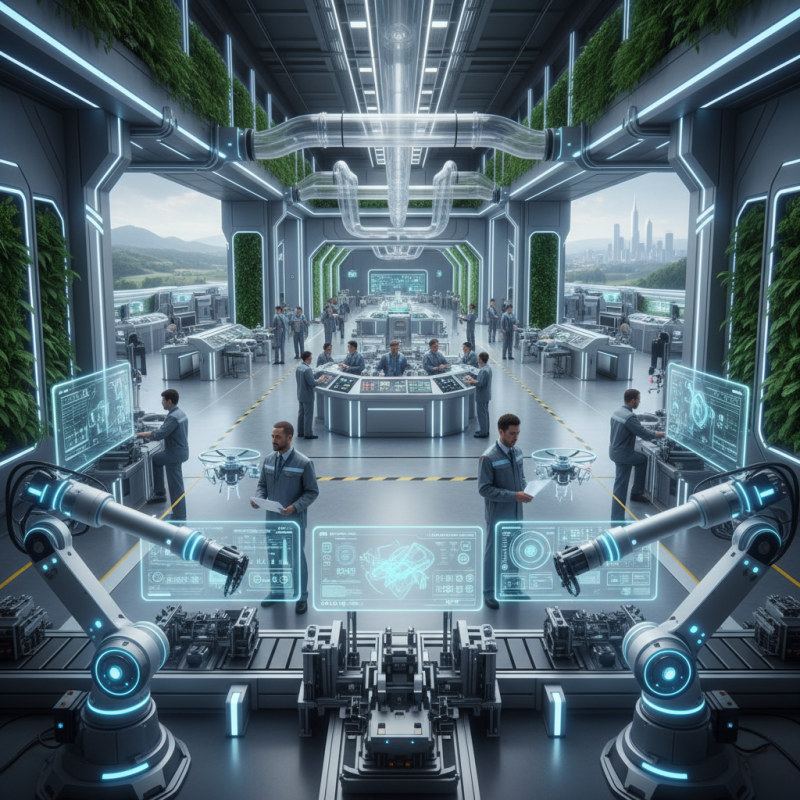

In addition, robotics is advancing significantly. Collaborative robots are designed to work alongside humans. They enhance productivity while ensuring safety. Yet, reliance on automation raises concerns about job displacement. Balancing technology with human workforces requires careful planning. The manufacturing landscape in 2026 will be shaped by these innovations, even as companies navigate the challenges they bring.

Automation is reshaping the landscape of manufacturing. According to a report by McKinsey, 60% of jobs in manufacturing could be automated by 2030. This shift raises concerns about job displacement for workers. Many fear that traditional roles will disappear, leaving a skills gap in the industry.

One notable statistic from the World Economic Forum indicates that up to 85 million jobs may be displaced by automation. Yet, the emergence of new roles, driven by technology, could create 97 million jobs. This presents a dilemma. How do we prepare the workforce for these changes? Upskilling and reskilling will be vital. Companies must invest in training programs to help employees transition.

Automation boosts efficiency significantly. Reports show that productivity can increase by 20-30% with smart manufacturing technologies. However, this efficiency comes with its own set of challenges. Companies often face implementation hurdles. Resistance to change among staff can lead to friction. The balance between technology and human touch is delicate. Embracing automation is essential, but so is addressing workforce dynamics thoughtfully.

Sustainable manufacturing is redefining how industries operate. Companies are exploring innovative materials that minimize waste. Advanced recycling technologies are essential. They transform waste into reusable materials. This process makes production more efficient and less harmful.

Energy-efficient machinery is another focus. These machines reduce energy consumption while maintaining output. However, many factories still rely on outdated practices. Shifting to green technologies can be challenging. It requires investment and training.

Moreover, supply chain transparency is crucial. Businesses are studying their entire production processes. Understanding sources of materials helps minimize environmental harm. Yet, tracing each component isn't always easy. There are many hurdles to overcome. The push for sustainability is necessary but complex. The future will demand continuous adaptation and reflection in these practices.

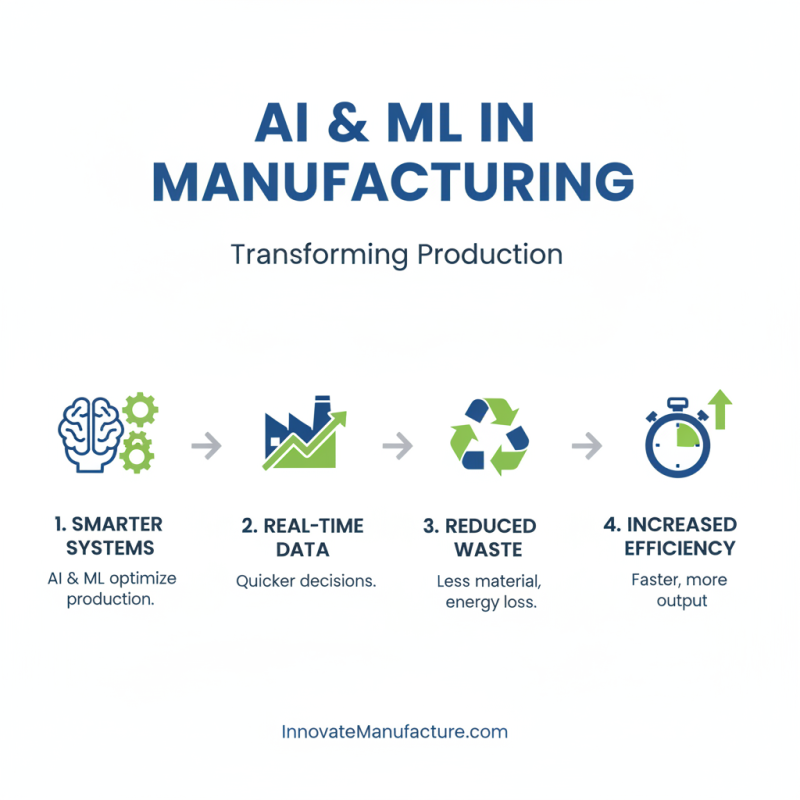

The integration of AI and machine learning in manufacturing is transforming the industry. These technologies create smarter systems that optimize production. Manufacturers can analyze data in real time, making quicker decisions. This leads to reduced waste and increased efficiency.

Implementing AI can be challenging, though. Many manufacturers lack the necessary skills to utilize these advanced technologies. Furthermore, data security becomes a major concern. Protecting sensitive information is critical as systems become more interconnected. Companies must address these issues while integrating new tools.

Despite the challenges, the benefits are significant. Predictive maintenance reduces equipment failure rates. Quality control improves as machines learn from past errors. However, it is essential to remain cautious and adapt as technology evolves. The journey is not flawless, but it offers a glimpse into a more efficient manufacturing future.

Smart factories are transforming how we perceive manufacturing. The Internet of Things (IoT) plays a crucial role in this shift. Machines can communicate in real-time. This connectivity boosts efficiency and reduces downtime. Sensor data helps identify potential issues before they escalate. However, reliance on technology raises concerns.

Data security is a significant challenge. Vulnerabilities in connected devices can lead to breaches. Companies must prioritize cybersecurity measures. Ensuring data integrity and protection is essential. Training employees in these new technologies is equally important. Many workers may feel overwhelmed or resist change. Addressing these issues requires thoughtful planning.

Moreover, not all innovations are seamless. Integrating IoT systems can be complex. Compatibility with existing equipment is often an obstacle. Companies must carefully evaluate their infrastructure. While IoT can enhance productivity, it also demands careful consideration and adaptation. Embracing this technology is a journey, not a destination.